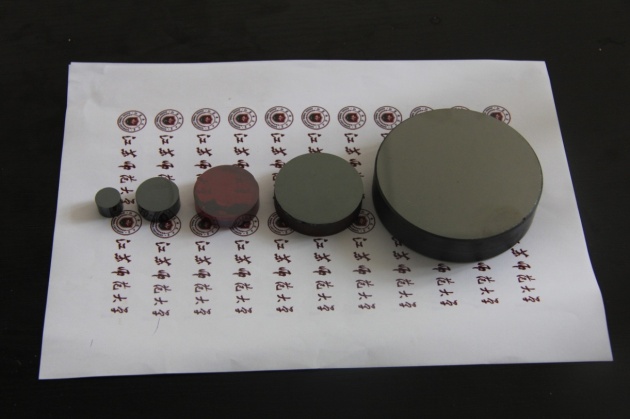

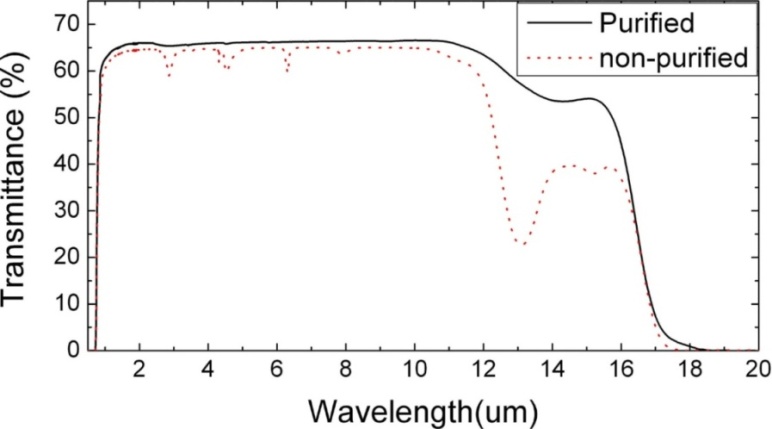

This project uses a specially designed purification approach and a homogenization technique to produce high quality chalcogenide glasses. The manufactured chalcogenide glasses have high purity, good optical uniformity, excellent infrared transmittance and good batch stability. They can be molded or machined into infrared lenses for thermal imaging systems, which have a number of significant applications in military weapons, civilian night vision, and industrial detections. These glasses can also be drawn into optical fibers and engraved gratings for infrared optics. The main properties of the glasses include: (1) transmittance range: 1-14 µm, which can also be customized to 0.5-10 µm and 2-20 µm; (2) maximum diameter: 150 mm; (3) maximum thickness: 100 mm; (4) thermo-optic coefficient: 20-100 x10-6/oC, which can also be customized to a smaller positive value or a negative value; (5) working temperature: < 200 oC; (6) thermal expansion coefficient: 12-20 x 10-6/ oC. These glasses are mainly used to meet the national defense demands for infrared transmission materials. High-purity chalcogenide glasses and devices are also provided to universities and institutes for scientific researches. At present, about 7.3 million RMB of economic benefits have been generated, mainly from post-processed chalcogenide glass products such as infrared optical fibers and infrared grating blanks. The chalcogenide glasses and devices have also been used in the researches of nonlinear optics, atmospheric sensing, infrared frequency selections, and thermal imaging deliveries by some institutes such as Australian National University, Anhui Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Soochow University, Shanghai Aerospace Control Technology Research Institute, etc.